Reference Guide Contents

OverviewProduct Safety Tests

- Dielectric Strength - Hipot Test

- Ground Continuity, Polarization, and Ground Bond Tests

- Insulation Resistance Test

- Leakage Current Test

Choosing the Right Test Equipment

Applications

Standards

Glossary of Terms

Need Assistance?

Hipot Test Equipment

- AC Hipot Testers

- AC/DC/IR Hipot Testers

- Multi-Channel Hipot Testers

- AC/DC/IR/GB/LC/Dynamic Function Electrical Safety Analyzer

- AC/DC/IR Hipot with Corona Discharge Detection

- Ultra-High Withstand Voltage Hipot Analyzer

Leakage Current Test Equipment

- AC/DC/IR/GB/LC/Dynamic Function Electrical Safety Analyzer

- Capacitor Leakage Current/IR Meter

- LC/IR/PD Battery Cell Insulation Tester

Ground Bond Test Equipment

LCR Meters

Wound Component Testers

- AC/DC/IR/DCR Hybrid Wound Component EST Scanner

- AC/DC/IR/Impulse(Surge)/DCR Wound Component EST Analyzer

- Impulse Winding Tester

Battery Safety Testers

Chroma Systems Solutions

19772 Pauling

Foothill Ranch, CA 92610

949-600-6400

Request a quote

Get our Newsletter: Click the link below to register.

Get our Newsletter: Click the link below to register.

Follow Us

How To: Electrical Safety Testing Reference Guide

In the electrical product business, product safety compliance is an important issue for several reasons. Manufacturers and distributors want to sell “safe products”. Consumers want to buy products with the assurance that they won’t be exposed to hazards. Product quality, reliability, user safety and company liability issues are real consequences of doing business today.

Regardless of your specific interest in safety testing, it is important for you to have a general understanding of product safety requirements and how they affect your device. Needed as well is an overall view of the regulatory compliance world and the specific steps in the process that may have a direct impact on your daily responsibilities.

The intent of this reference guide is to explain the need for and the basis of Electrical Safety Testing (EST). This guide provides a general overview of the regulatory framework and approval process and explores the specific manufacturing responsibilities and test procedures associated with electrical safety testing.

Keep reading: Reference Guide Overview

The material in this guide is for informational purposes only and is subject to change without notice. Chroma assumes no responsibility for any error or for consequential damages that may result from the misinterpretation of any content contained on this site.

Additional Improvements

Below are additional improvements to safety test equipment not defined by the safety standards but based on feedback from manufacturers.

Simultaneous Testing of Ground Bond and Hipot

When manufacturers are producing high volumes of product, even a few seconds saved can equate to improved process times and higher volumes. Simultaneous testing of ground bond and hipot can cut the actual test times in half, saving the manufacturer process time and money.

Many safety test equipment manufacturers have developed high-voltage and high-current multiplexers to allow multiple products to be tested from a single safety test device. These are referred to as scanners and multiplexers, and capacity varies from one or two devices to tens and hundreds of devices.

Corona Discharge / Flashover Detection / Breakdown

All hipot and dielectric test equipment has the capability to detect a breakdown, and some can detect flashover, but only a few have the added capability to detect corona discharge. Although safety agencies have not included any requirement to measure the corona discharge in the safety test requirements, by accurately measuring the leakage current dynamically in very small levels, it is possible to determine if the unit is in one of the following conditions:

Corona Discharge: an electrical discharge brought on by the ionization of a fluid surrounding a conductor, which occurs when the potential gradient exceeds a certain value but conditions are insufficient to cause complete electrical breakdown or arcing. Corona discharge may be an early symptom of an impending breakdown.

Flashover: an electrical breakdown of a gas that produces an ongoing plasma discharge, resulting from a current flowing through normally nonconductive media such as air.

Breakdown: a rapid reduction in the resistance of an electrical insulator that can lead to a spark jumping around or through the insulator. This may be a momentary event such as ESD or lead to a continuous arc discharge if protective devices fail to interrupt the current in a high power circuit.

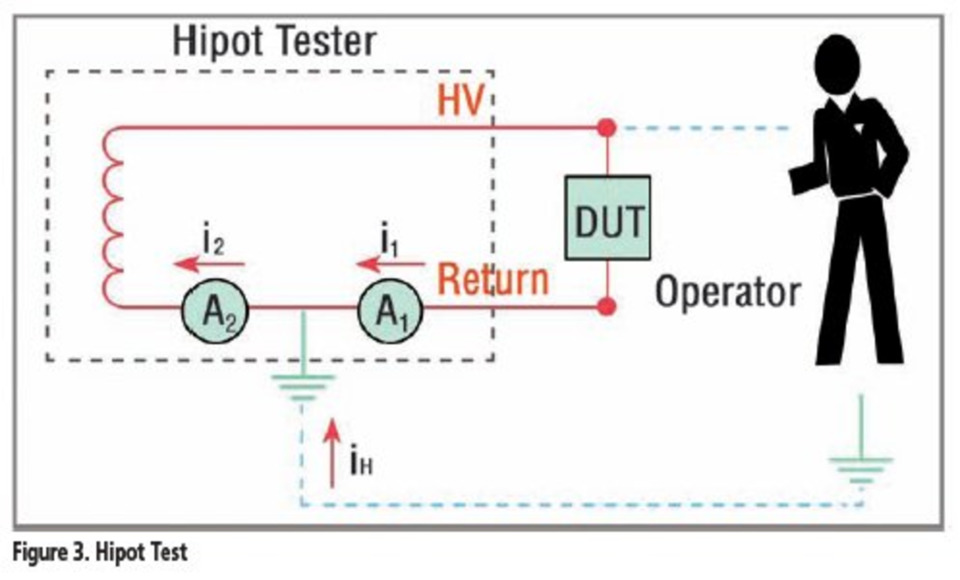

Figure 2 shows the association of these three conditions.

More information on Corona Discharge detection and the instrument that can test for it.

Open Short Check

It is important to know if the DUT is properly connected to ensure that the hipot test or insulation resistance test has been performed. One test equipment manufacturer has developed a method of ensuring the connections to the DUT are normal/open/ or shorted referred to as the open short check.

Based on the fact that any equipment with conductors separated by an insulator will result in some type of capacitance, and applying a high frequency and measuring the impedance, then it can be determined if the connection is open, shorted, or normal.

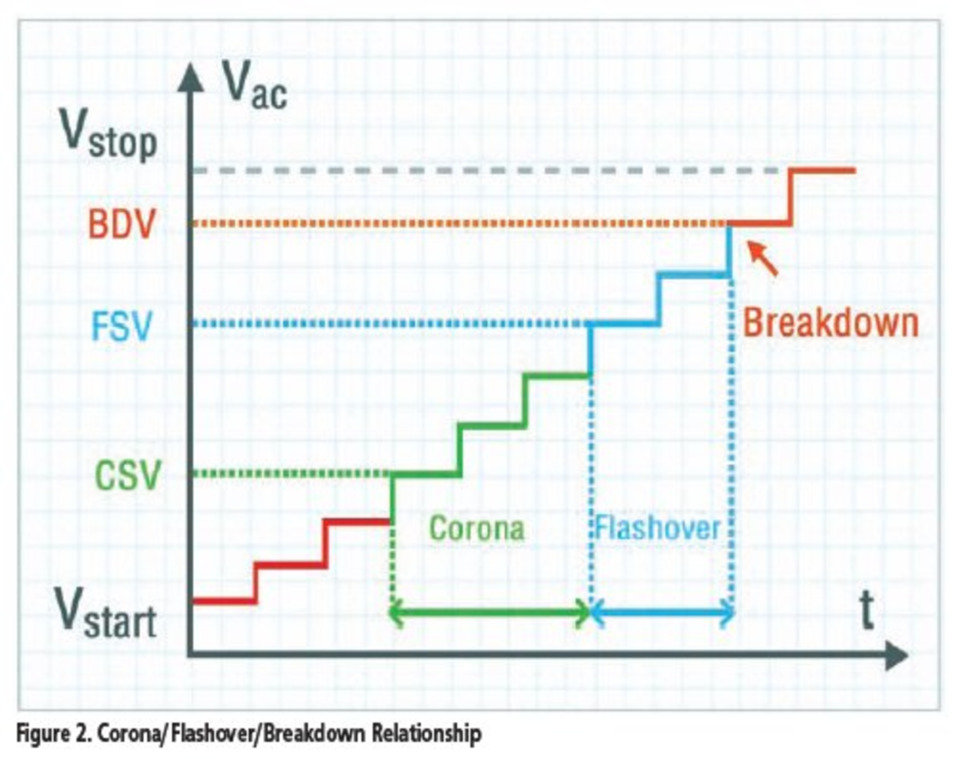

Ground Fault Interrupt and Operator Protection

Hipot and dielectric withstand test equipment can present an electrical shock hazard to the test operator. Test equipment manufacturers have included a ground fault interrupt circuit to help prevent the operator from being electrically shocked. A ground fault exists whenever currents i1 and i2 are not equal, as shown in Figure 3.